What Is a Deep Ultraviolet Fiber Laser?

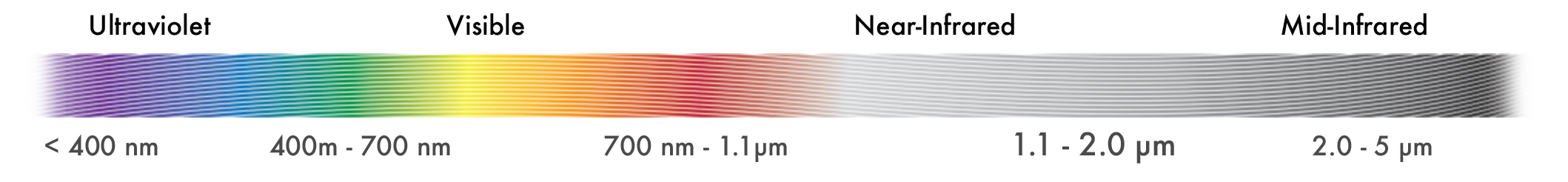

"Deep ultraviolet (DUV)" generally refers to ultraviolet lasers with a wavelength shorter than 300 nanometers (nm). Starting from infrared beams (approximately 1000 nm), fiber lasers achieve deep ultraviolet wavelengths through a wavelength or frequency multiplication process. By focusing the infrared laser beam through a nonlinear crystal, the wavelength is precisely halved to generate the second harmonic. Repeating this process halves the wavelength again, expanding the wavelength range of fiber lasers to the fourth harmonic.

Compared with lasers operating at the more commonly used infrared and visible wavelengths, deep ultraviolet lasers offer significant advantages in specific applications. Combined with the more reliable and easier-to-integrate fiber laser structure, deep ultraviolet wavelength lasers are finding increasing use across various industries. They play a crucial role in numerous applications such as micromachining, semiconductor manufacturing, and advanced scientific research.

Advantages of Deep Ultraviolet Fiber Lasers

Higher Precision and Resolution

Lasers with shorter wavelengths minimize diffraction effects, allowing the beam to be focused into a smaller spot compared to longer-wavelength lasers. Fundamentally, the diffraction limit is described by the Rayleigh criterion, which states that the minimum distinguishable spot size is approximately half the beam wavelength. In applications requiring high precision—from precision machining tools to microscopes—smaller spots enable higher spatial resolution.

Improved Absorption

Ultraviolet light has high photon energy and is strongly absorbed by the shallow surface layers of bulk materials. High-energy deep ultraviolet pulses locally heat the submicron layers of bulk materials, exciting or ionizing the material at the molecular or atomic level. At sufficiently high energy densities, most of the heat is dissipated from the plasma generated at the target. This process, known as photoablation, reduces the heat-affected zone (HAZ) and largely eliminates adverse thermal effects such as unintended melting and cracking. For many materials—especially transparent or heat-sensitive ones—shorter wavelengths are essential to achieve the absorption required for high-quality results.

Industry-Leading Deep Ultraviolet Laser Technology

Traditionally, users seeking the benefits of ultraviolet and deep ultraviolet lasers had to accept devices that were unreliable, expensive, or difficult to integrate. Short component lifespans, bulky designs, and consumables like gases limited the widespread adoption of deep ultraviolet lasers. Only Precilasers offers a unique combination of power, reliability, and operational stability, making deep ultraviolet wavelength lasers affordable and robust enough for daily industrial use.

Industrial Reliability:Precilasers’ deep ultraviolet fiber lasers use specialized nonlinear crystals, which are grown in Precilasers’ dedicated crystal facilities. The quality of these crystals inhibits degradation, ensuring longer-lasting power stability.

Rugged, Compact Design:Unique fiber laser technology allows Precilasers’ deep ultraviolet fiber lasers to accommodate higher power in a smaller footprint, with shock and contamination resistance. This makes them easier to integrate into almost any industrial environment.

Flexible Applications:Precilasers provides continuous-wave (CW), nanosecond-pulsed, and ultrafast options, with higher power, better beam quality, and more configurations. These features enable superior performance across a wider range of applications.